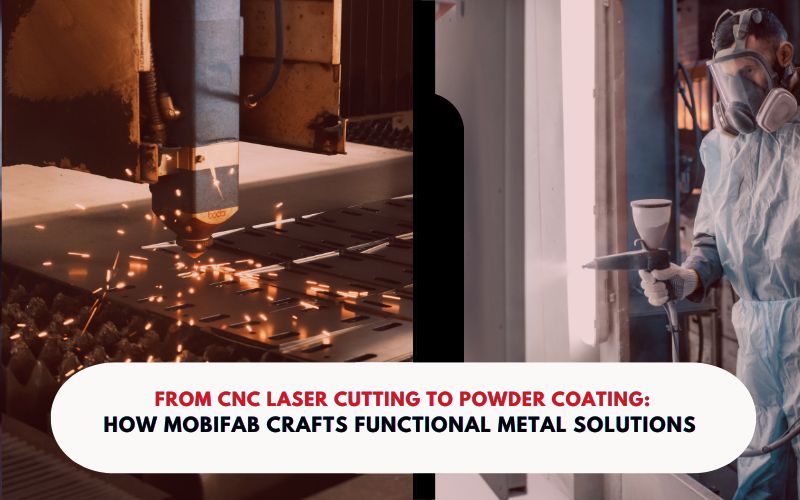

From CNC Laser Cutting to Powder Coating: How MobiFab Crafts Functional Metal Solutions

Are you ready to unleash the magic of metal craftsmanship?

Mobifab changes raw metal into excellent functional solutions to meet various requirements. Moreover they provide quality assured products with modern techniques and expert staff

Now let us check out the steps from right from CNC laser cutting to powder coating and find out how each step is vital to our metal fabrication.

The Power of Precision

And this is where we part ways. This teaching is capable of the accurate cut in numerous metals such as brass and aluminum. Study has discovered that the global machine market will be up to $100 billion by 2025, and this increase indicates the general production need for precision and efficiency.

Here we use machines that can achieve tolerances of ±0.1 mm. It can also manage complicated designs to make detailed patterns and shapes. It increases both the functionality and look of the products.

Speed & Efficiency

They are essential in any manufacturing process, and CNC laser cutting excels in both areas. The automation offered by CNC systems eliminates the need for manual adjustments and lowers setup time.Once programmed using dedicated computer softwares, these cutting machines can consistently repeat the same design with minimum operator intervention, resulting in faster productions. The laser’s cutting speed also adds to the efficiency which allows the makers to meet the deadlines and increase the productivity to a great extent.

Welding: Joining Forces

Metal cutting is followed by welding processes. This involves blending two or more metal parts together to make a single, consolidated design. Mobifab provides strong , long lasting joints through techniques such as TIG and MIG. Welding is vital for creating strong products that can bear wear and tear.

Quality Assurance

Quality monitoring is an essential part during the process. The expert welders fulfills the industry demand through rigorous training. Each product is checked to ensure quality and strength after welding. Mobifab stands out in this sector just because of their focus on product quality.

The Finishing Touch: Powder Coating

When the welding is done, a finishing touch is what powder coating is all about. It is a method in which a dry powder is sprayed on the metal surface and it is then heated to cure it. The outcome is a very attractive smooth finish that is not only loyal to the original look but also keeps the product for a longer time.

It has a lot of benefits compared to the traditional type of painting. In addition the coated layer is thick, uniform and can bear the color fading wear and tear as well as scratches from the start.The Powder Coating Institute indicates that the worldwide market is forecasted to reach $15 billion by 2025, while growing at a CAGR of 6.5%. Such an increase is a clear indication of this becoming the most favored finishing technique.

Eco-Friendly Option

The eco-friendliness of powder coating is another important benefit.They are safer alternatives for both human health and environment as they do not produce any volatile organic compounds unlike age-old liquid paints. Mobifab is dedicated to sustainability and their goal revolves around minimizing environmental hazards related to powder coating.

Fabrication with Functionality in Mind

What sets MobiFab apart is its emphasis on functionality and usability, not just technical expertise. It all starts with understanding how the product is going to be used.

For example,

Hospital workstations require non-porous materials that can endure frequent cleaning with harsh chemicals.

Laboratory benches need specific dimensions and chemical-resistant coatings.

Industrial enclosures must be sturdy, properly ventilated as well as protect against corrosion .

By working closely with designers and engineers from the start, they guarantee that the metal parts produced perfectly fits into the final product. Each curve, weld and finish has a targeted function.

Custom Solutions for Every Need

At Mobifab we always prioritize the unique needs of each and every client. Our team collaborates with clients to create and produce customized metal solutions that fulfill the demand. Both for single projects and large scale manufacturing we have the in-depth knowledge and technology to deliver products.

Practical Uses

Our products are utilized in various sectors such as construction, automotive and furniture design. Vehicle production uses our metal parts as strength and accuracy are the key points there. In the construction sector too , our metal structures give support and stability for building projects.

Final words

From CNC laser cutting to the powder coating process,showcases not only skill and knowledge, but also passion and commitment. Our finished products showcase both engineering expertise as well as aesthetics.

Determining the durability of the products is crucial for us and we show that how technical expertise and expert staff come together to create solutions

MobiFab: Where Precision Meets Performance, Every Time.